Custom Plastic Enclosure Pricing: The Complete Guide to Estimating Your Budget

Discover how to estimate the cost of your custom plastic enclosure. From prototype to production, learn what influences the price and how LTP enclosure technology helps.

Design and manufacture of custom enclosures, covers and plastic parts via the NO MOULD sheet plastic bending technology.

The most suitable process for the production of small and medium series.

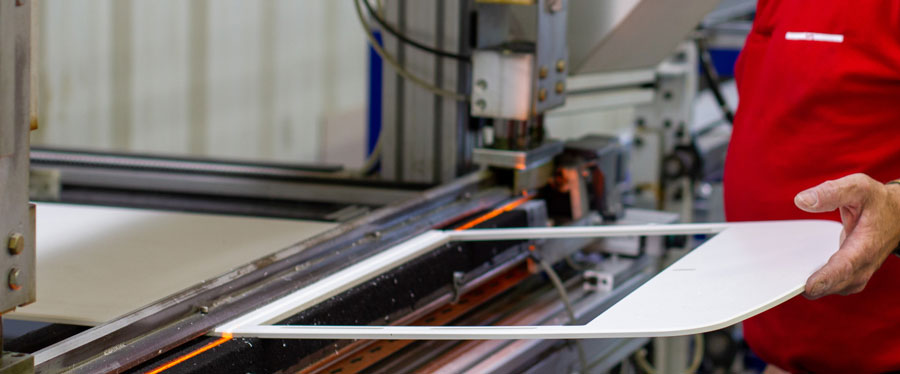

Our proprietary technology, Plastic Sheet Bending, was invented to design and manufacture custom-made, MOULDLESS plastic enclosure solutions for small and medium-sized production runs.

Thanks to this innovative process, LTP offers its customers a fast and economical solution for their needs in terms of enclosures, covers and customised mechanical parts.

As a human-sized company, LTP provides its customers with advice and recommendations for the success of all their projects.

Customisation is

what we do !

All our proCesses

are certified

Since its creation, our plastics processing company in France, LTP, has rapidly found its market, not only in France, but also abroad. Indeed, the sheet plastic bending technology process specifically meets the needs of small and medium-sized production runs. This is a daily problem for many companies in Europe, in all sectors :

Discover how to estimate the cost of your custom plastic enclosure. From prototype to production, learn what influences the price and how LTP enclosure technology helps.

LTP enhances its production capacity with a new large-format digital printer, offering high-precision, custom marking directly on plastic enclosures – without moulds and with full design freedom.

Can plastic manufacturing be eco-friendly? LTP proves it’s possible with custom enclosures made from recycled and optimised materials, designed to last.

Nous sommes ravis d’annoncer la participation de LTP au salon Electronica 2024, qui se tiendra à Munich, en Allemagne, du 12

By designing more than 10,000 customised projects since its creation, the LTP team has developed a close partnership with all its customers, both in France and in Europe.

In most countries or regions, LTP has exclusive partnerships with technical sales teams dedicated to “Sheet Plastic Bending”.

Our customers are spread across all types of companies, from start-ups to large groups.