Introduction In the dynamic world of electronics, original equipment manufacturers (OEMs) face a major challenge: how to design and produce bespoke plastic enclosures in small and medium production runs while guaranteeing quality, cost and on-time delivery? The answer lies in a structured and efficient approach. At LTP, we have developed recognised expertise in turning this challenge into an opportunity, ensuring that our customers receive optimised production tailored to their specific needs.

Understanding the Key Design and Manufacturing Stages

Step 1: Analysis of needs and specifications

The first step is to understand the OEM’s specific needs. This involves gathering detailed information about the product, its use and its environment. To do this, LTP engages in an in-depth dialogue with its customers to establish precise specifications. This process is crucial to ensure that the enclosure designed meets all technical and aesthetic requirements.

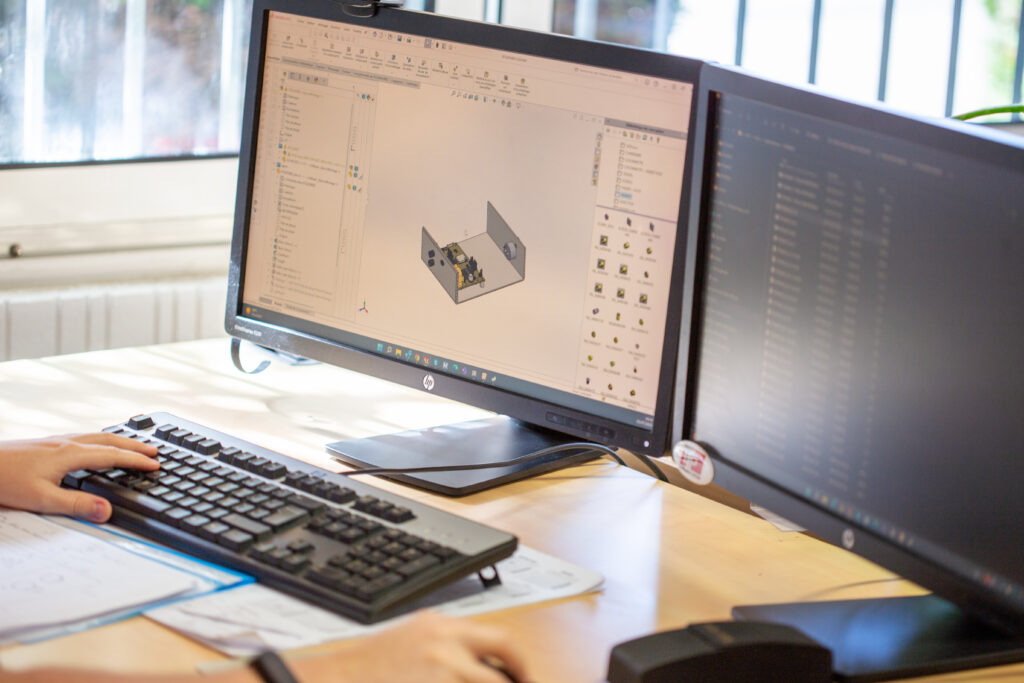

Step 2: Designing the enclosure

Once the specifications have been established, LTP proceeds to design the enclosure. Using advanced tools such as SolidWorks, our design office creates 3D models that enable the final product to be visualised. This stage includes taking into account mechanical, chemical and thermal constraints, as well as ergonomic aspects. Our team of project managers work closely with our engineers and technicians to ensure that the design is both functional and aesthetically pleasing.

Step 3: Prototyping

Prototyping (1st series) is an essential stage in the manufacturing process. At LTP, we create physical prototypes that include all the finishing touches required (marking, painting). This prototype serves as the contractual basis for series production and enables tests to be carried out to validate the design. Any necessary adjustments can then be made before moving on to production.

Step 4: Industrialisation and series production

The industrialisation of enclosures in small and medium production runs requires meticulous planning. LTP uses appropriate processes that allow great flexibility while maintaining high quality standards. Our manufacturing workshops are equipped to carry out operations such as machining, folding and bending, enabling us to respond quickly to specific customer requests without the need for tooling or custom moulds.

Step 5: Quality control and packaging

Once production is complete, each batch of cases undergoes rigorous quality control. LTP guarantees that each product meets ISO 9001 standards, ensuring customer satisfaction. Packaging is also optimised to ensure that the boxes arrive at the customer’s premises in perfect condition, while avoiding over-packaging in line with its CSR approach.

Example of a project: Medical equipment enclosure

Take the example of a project we carried out for an OEM in the medical sector. The objective was to design an enclosure that was resistant to chemicals, while complying with strict safety standards. After an in-depth analysis of the requirements, our team came up with a design that incorporated specific ergonomic features, such as optimised access zones. The prototype was quickly validated, and small-scale production began within a very short timeframe, enabling the customer to successfully launch its product on the market.

Conclusion

Designing and manufacturing bespoke plastic enclosures in small and medium production runs is a challenge for OEMs, but with the right approach, it becomes an achievable reality. LTP is there to support you every step of the way, guaranteeing quality production, on time and on budget.

Discover Our Custom Solutions

To find out more about how LTP can help you industrialise and manufacture your plastic enclosures, please contact us. Together we can turn your ideas into real successes. Visit our website or contact us directly to discuss your project. Your success is our priority!

At LTP – La Tôlerie Plastique, we understand the importance of combining functionality, design and cost when designing bespoke enclosures. Whether you require a standard or customised solution, we are ready to support you with high-quality products tailored to your specific needs.

Contact us today to discuss your project and find out how we can design and manufacture bespoke enclosures for you, quickly and efficiently, and within your budget!

Tel : +33 (0) 2 35 54 63 40

Mail : sales@ltp.fr

Find further information about the NO MOULD LTP Technology: ✅Custom Design : Company LTP : Design of bespoke plastic enclosures ✅Prototype : A prototype to validate your custom design!

✅Mounting solutions : Accessories for mounting and fixture solutions

✅Impermeability : IP standards: Solid and liquid tightness (max IP65)