Custom plastic enclosures protect your electronic components, even under the most demanding conditions. With standards like the IP65 rating, they ensure optimal protection against dust and water. Discover how LTP achieves this performance through its expertise and the precise selection of materials and gasket designs.

Plastic Enclosure for Lone Worker Devices: Waterproof and Durable – A Common Requirement

Monitoring devices for lone workers require reliable and waterproof enclosures, as these devices are often used outdoors. With customised solutions, LTP meets IP65 standards, ensuring optimal protection for electronic components.

- A design that diverts liquids away from openings.

- A rigorous selection of gasket materials.

- Reinforced fixing points using blind inserts and complementary sealing paste.

How to Choose the Materials and Shape of Gaskets for Your Enclosure?

The performance of a waterproof enclosure largely depends on the materials and shape of its gaskets. Below is an overview of the materials used by LTP, along with their advantages and disadvantages:

Gasket Materials Used by LTP to Protect Your Electronics:

- Neoprene

- Avantages :

- Weather-resistant, and resistant to oils and moderate chemicals.

- Good value for money.

- Disadvantages

- Limited resistance to extreme temperatures (maximum ~120°C).

- Avantages :

- Rubber

- Advantages :

- Excellent elasticity and sealing properties.

- Good resistance to abrasion and impacts.

- Disadvantages :

- Less resistant to aggressive solvents and UV rays.

- Advantages :

- Silicone

- Advantages :

- High thermal resistance (-60°C to +200°C).

- Excellent durability and flexibility, even in extreme conditions.

- Compatible with medical environments.

- Disadvantages :

- Less resistant to abrasives and hydrocarbons.

- Higher cost compared to other materials.

- Advantages :

- Neoprene EMI Gasket (Electromagnetic Interference)

- Advantages :

- Blocks electromagnetic interference and protects sensitive components.

- Good sealing against dust and liquids.

- Disadvantages :

- Peut nécessiter un entretien spécifique pour conserver ses propriétés conductrices.

- Advantages :

Gasket Shapes for Your Plastic Enclosure: O-Rings or Flat Gaskets?

- O-Rings

- Advantages :

- Suitable for circular areas or surfaces with constant contact.

- Provide enhanced sealing under pressure.

- Disadvantages :

- May be less effective on irregular surfaces.

- Advantages :

- Flat Gaskets

- Advantages :

- Excellent for covering large areas or complex shapes.

- Easy to install and adjust.

- Disadvantages :

- Less effective under high pressure unless combined with sealing paste.

- Advantages :

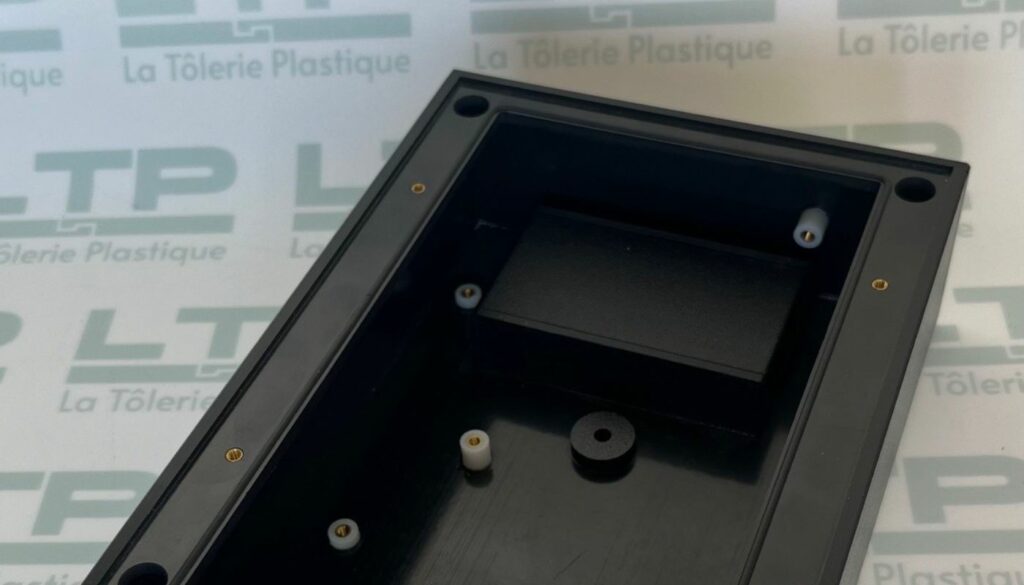

Case Study: An IP65 Enclosure for a Lone Worker Device

A manufacturer of safety equipment for lone workers required a waterproof enclosure to protect electronic components in a device intended for outdoor use. Here’s how LTP addressed this challenge:

- Tailored Design: A “U” shape to redirect water splashes.

- Selected Materials: Use of silicone gaskets for their durability and weather resistance.

- Optimised Shape: Flat gaskets combined with sealing paste to cover large surfaces.

- Hermetic Fixings: Integrated blind inserts to prevent infiltration through fixing points.

Result: A functional prototype meeting IP65 standards was delivered within a few weeks, ready for testing and client presentations.

LTP: Customised Solutions for Your Waterproof Enclosures

With expertise in Plastic Fabrication, LTP supports you in the design and manufacture of customised enclosures that meet the strictest waterproofing requirements. We tailor each project to your constraints, optimising materials and designs.

📞 Contact us today for a free project offer.

Phone : 0033 (0)2 35 54 63 40 | 📧 Email : sales@ltp.fr