The design of green spaces and living walls within construction or renovation projects presents a challenge for architects, economists, and design offices. Unusual dimensions, specific requirements, and the need for tailor-made solutions call for customised products. However, creating specific moulds for small and medium-sized series can quickly become costly and time-consuming. In this context, custom-made plastic containers provide an ideal solution, particularly thanks to the LTP enclosure technology.

Challenges in designing green spaces with unique dimensions

In renovation or outdoor development projects, the demand for planters for outdoor spaces and other living wall solutions is often complex. Architects and economists frequently face non-standard dimensions that are difficult to accommodate with conventional industrial products. Producing moulds for small series is not only unprofitable but also highly time-consuming. The ideal solution? A flexible, fast, and tailor-made process that avoids these obstacles while meeting the requirements of each project.

The LTP enclosure solution: flexibility and customisation

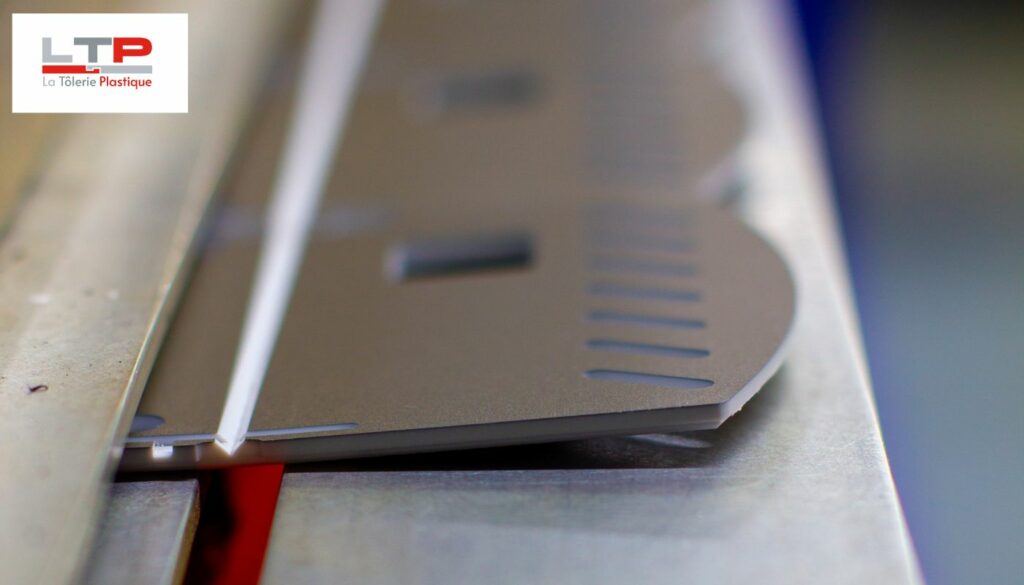

The custom sheet bending process offers numerous benefits for professionals in the construction industry. Thanks to this technology, it is possible to create custom-made plastic containers without the need for costly moulds. This allows for specific requirements in terms of dimensions, shape, and functionality to be met while ensuring an economical and fast solution.

Key technical advantages

- No initial investment: The absence of specific moulds eliminates the costs associated with their design and production.

- Flexibility: The process allows for modifications and technical developments throughout the project’s duration, ensuring continuous adaptation to client needs.

- Complete customisation: Every project is unique, and we offer fully tailor-made solutions, whether in terms of dimensions, shape, or aesthetic finish.

- Short production times: Unlike conventional solutions, manufacturing times are reduced to 2 to 6 weeks, ensuring essential responsiveness for urgent projects.

- Safety and environmental compliance: Fire-rated plastics are available on request, and an approach to eco-design can be implemented for environmentally friendly projects.

Case study: Planters for an outdoor development

Consider the example of a green space development project in a residential complex. The design office faced specific dimensions for planters to be installed on a living wall. Thanks to LTP sheet bending technology, it was possible to create custom-made plastic containers that fit perfectly within the available space and met the client’s aesthetic and functional needs, without requiring costly moulds. The result? A seamlessly integrated, visually appealing, and on-time solution at a controlled cost.

Why choose LTP for your custom projects?

Choosing LTP for your custom-made plastic enclosures means benefiting from unique expertise in mould-free plastic product design. Our flexible and rapid process allows for the realisation of both technical and aesthetic projects while reducing costs and lead times. Additionally, our team of experts is available to support you in defining your requirements and bringing your projects to life.

📞 Contact us today to discuss your custom enclosure needs and discover our innovative solutions.

Phone: 0033 (0)2 35 54 63 40 | Email: sales@ltp.fr