Effective Protection Against Electromagnetic Interference

Introduction

Industrial measurement equipment is subject to electromagnetic interference (EMI), which can affect the accuracy of sensors and electronic instruments. To ensure proper functionality, it is essential to design enclosures that comply with electromagnetic compatibility (EMC) requirements.

Traditionally, metal enclosures are used for EMI protection, but they have disadvantages: high weight, high production costs, and limited design flexibility. With mould-free LTP enclosure technology, it is now possible to design bespoke plastic enclosures that provide effective protection against electromagnetic interference—without the constraints of metal solutions.

The Challenges of EMI in Industrial Measurement Equipment

EMI consists of electrical disturbances from external electromagnetic fields or internal components. These can cause measurement errors, data loss, and even equipment malfunction. Measurement devices must therefore comply with strict standards, such as:

- EN 61000-6-4 for industrial environments,

- CISPR 11/22 for electronic equipment,

- DO-160 for aerospace applications.

Traditional solutions include metal enclosures, conductive paints, and EMI gaskets. However, for small series or specific designs, these solutions can be costly and difficult to implement.

A Bespoke Solution with LTP enclosure technology

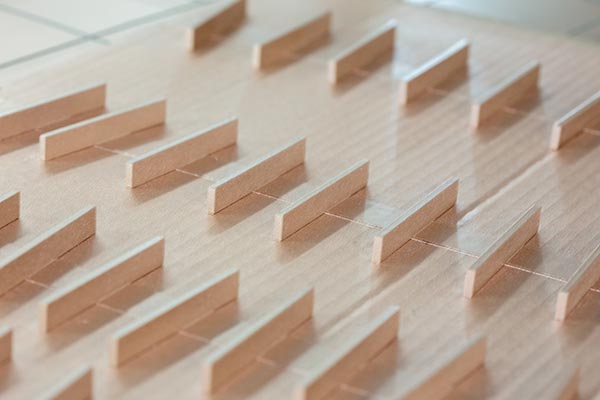

Mould-free LTP enclosure technology allows the production of plastic enclosures with EMI shielding by applying a copper-based conductive paint. This method combines design flexibility with cost reduction, making it ideal for small and medium production runs of up to 2,000 parts.

Effective EMI Protection

- Conductive interior coating with EMI attenuation exceeding 60 dB depending on frequency,

- Optional EMI gaskets for optimal electrical continuity.

Advantages of Bespoke Plastic Enclosures

- No moulding constraints: fast and cost-effective customisation,

- Up to 40% weight reduction compared to aluminium,

- Short production lead times (2 to 6 weeks),

- Custom aesthetic finishes (paint and marking).

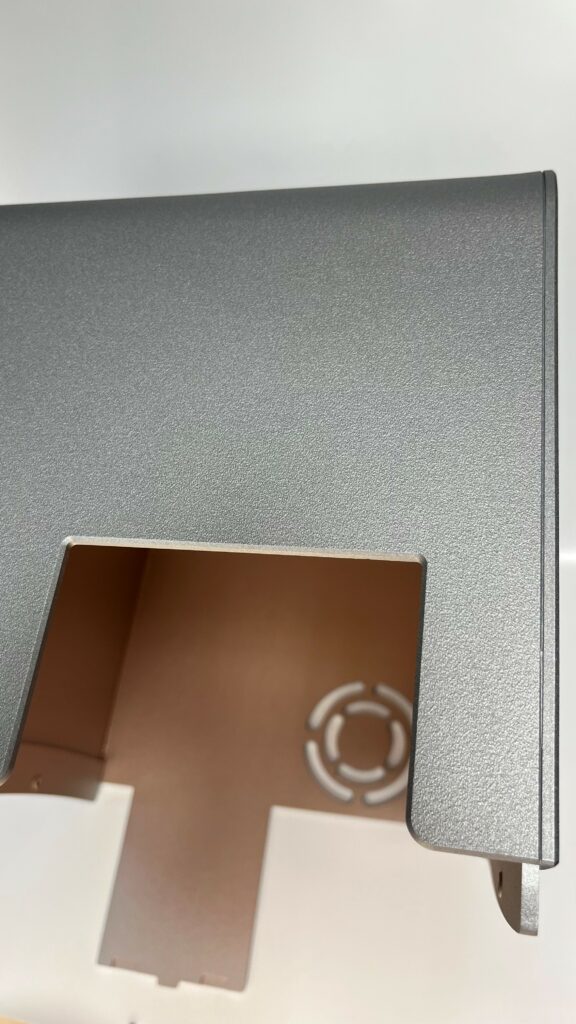

Case Study: EMI-Shielded Plastic Enclosure for a Measurement Sensor

Background

A manufacturer of industrial measurement instruments required a bespoke enclosure integrating effective EMI protection while remaining lightweight and cost-efficient.

Solution

- Design of a plastic enclosure with internal conductive coating,

- Manufactured in 4 weeks, compared to 12 to 16 weeks for a moulded solution.

Results

- 35% weight reduction,

- 30% lower cost compared to a metal enclosure,

- Full EMC compliance and validated performance in customer testing.

Why Choose LTP for Your Bespoke Enclosures?

With LTP enclosure technology, we design high-performance plastic enclosures optimised for EMC protection and tailored to the requirements of measurement equipment.

We offer:

✔ A mould-free, flexible, and cost-effective solution,

✔ Proven EMI shielding integration,

✔ Personalised technical support,

✔ Reduced production lead times.

📞 Contact us today to discuss your bespoke enclosure requirements and discover our innovative solutions.

📞 Phone: 0033 (0)2 35 54 63 40 | 📧 Email: sales@ltp.fr