The link between plastics manufacturing and eco-responsibility may not be obvious to everyone. However, through consistent and rigorous practices, LTP demonstrates that it is possible to work with plastics such as ABS, PC, PMMA, and PVC while minimising environmental impact.

Discover how La Tôlerie Plastique, specialising in the production of custom-made plastic enclosures for electronic and mechanical applications, adopts sustainable practices while meeting the technical and economic demands of its clients.

LTP’s Eco-Responsible Initiatives in Custom-Made Plastic Enclosure Design

1. Optimised Design from the Start

At LTP, design is a crucial stage for balancing technical performance, aesthetics, and material minimisation. The team collaborates closely with clients to create bespoke enclosures that protect, encase, or enhance electronic components.

For instance, designs may include a reinforced base to ensure mechanical rigidity while using thinner material for the upper part to reduce weight and costs.

The primary goal is to deliver a solution perfectly tailored to the project’s technical requirements, budget, and aesthetic preferences.

2. Precise and Material-Efficient Manufacturing

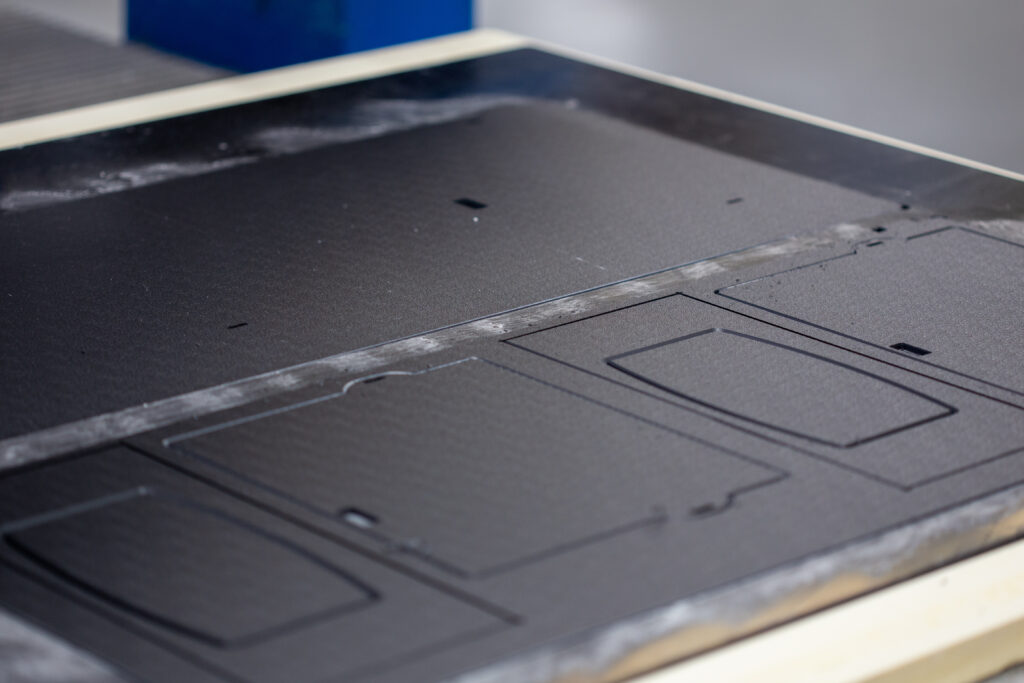

The technical team at LTP combines the expertise of a Design Office and a Methods Department to develop tailored manufacturing processes. Once the design is validated, machining programs are created to ensure optimal material usage.

For example, two U-shaped pieces are positioned on a sheet of plastic so they interlock perfectly, minimising material waste.

3. Recycling and Reusing Offcuts

At LTP, all material offcuts are systematically collected for repurposing. In collaboration with specialised partners, LTP ensures that these materials are not wasted.

For example, ABS offcuts are shredded on-site and returned to ABS sheet suppliers, who reintroduce them directly into their manufacturing processes. This virtuous cycle reduces environmental impact while optimising resource usage.

4. Offering Sustainable Design Options

LTP supports its clients in eco-conscious projects by offering:

- Recycled ABS: A sustainable alternative that maintains technical performance while reducing carbon footprint.

- Biodegradable materials: Available for specific applications.

- Bio-based materials: Also available for certain specialised uses.

Additional Tips for Sustainable Plastics Manufacturing in Custom-Made Enclosure Production

LTP takes its environmental efforts further by adopting complementary practices for more eco-responsible plastics manufacturing:

- On-demand production: Reducing unnecessary stock and producing only what is needed to avoid waste.

- Lightweight product design: Creating lighter enclosures that use less material while remaining robust and functional.

- Reduced transport emissions: Sourcing raw materials locally and optimising supply chains.

- Increased durability: Offering robust, reusable designs that extend product lifespan, avoiding frequent replacements.

Why Choose LTP for Eco-Responsible Plastic Enclosures?

By choosing LTP, you select a partner committed to eco-responsibility. Our custom-made plastic enclosures, designed with optimised and recyclable materials, are perfectly suited for mechanical applications while meeting high standards of durability and performance.

Contact us today to discuss your projects and discover our sustainable, tailor-made solutions.

📞 Phone: +33 (0)2 35 54 63 40 | 📧 Email: sales@ltp.fr