In the world of electric mobility, protecting batteries and their electronic components is crucial, especially in environments with high humidity and dust. A reliable enclosure with a high level of protection is essential to ensure the proper functioning and durability of battery packs, their electronics, and chargers.

Custom Design Example: LTP Plastic Enclosure Project Reference DT22040030

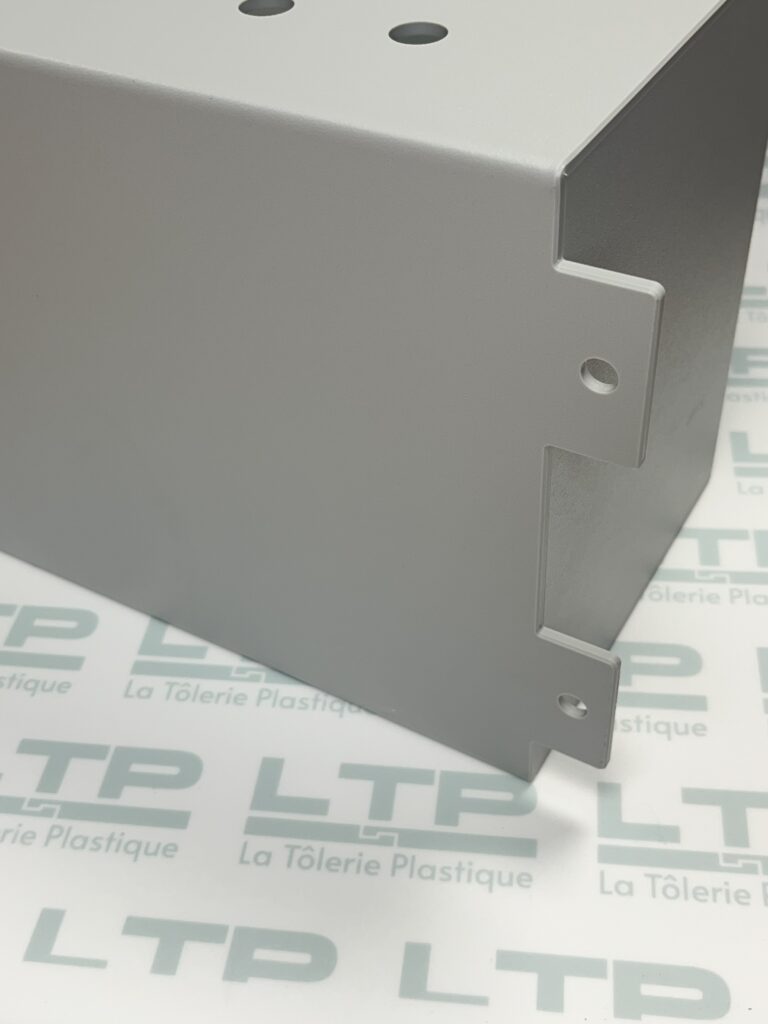

This project showcases the benefits of LTP’s plastic enclosure design for battery packs, chargers, or docking stations with IP65 protection. The enclosure consists of 12 individual pieces made from high-quality ABS material, 3 and 4 mm thick.

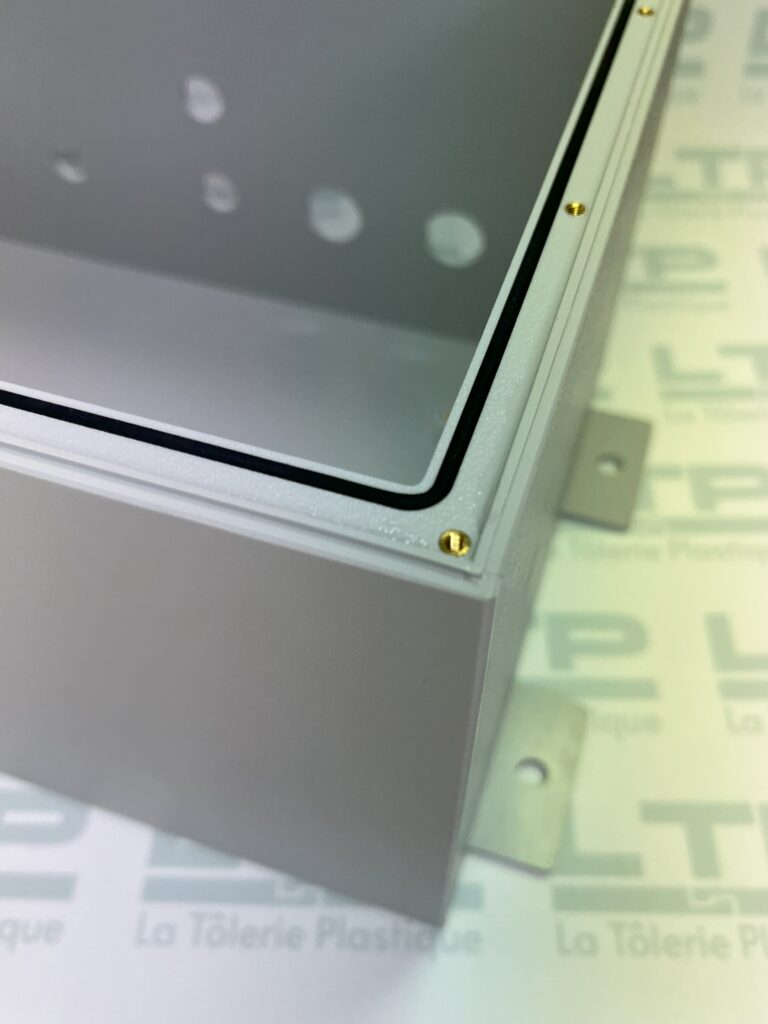

Fixing Elements for Electronics:

- Standoffs with brass inserts

- Sealing cord to achieve IP65 protection

Advantages of Plastic Tolerie Design:

- Robust Construction: The ABS material ensures a solid and durable structure.

- Secure Fixing: The use of brass inserts in the standoffs or belt ensures secure fastening of electronic components.

- IP65 Protection: The sealing cord provides high protection against moisture and dust.

- Cost Savings: The enclosure is manufactured without tooling costs, offering an economical solution for the customer.

The LTP DT22040030 enclosure project is a remarkable example of custom plastic enclosures providing an economical solution for electric mobility applications requiring high protection. Thanks to LTP’s innovative approach, customers can obtain high-quality and reliable products without the need for costly tools or moulds.

CUSTOM PLASTIC ENCLOSURE WITHOUT MOULD – IP65 PROTECTION

For technicians and engineers aspiring to transform their electronic device into a commercial success, the TOLERIE PLASTIQUE process offers a perfect solution between 3D printing and injection molding for small and medium series. As a designer and manufacturer, we offer unmatched flexibility:

- No specific mold, tailored to your needs

- Flexibility for all modifications, without constraints

- No significant initial investment

- 100% adapted to your target and application

Start your project with LTP today: Request a quote