The working conditions of electronic equipment can be harsh. Ensuring optimal protection is essential. Industrial sectors, particularly those handling sensitive electronic devices such as spectrometers, have specific requirements for mechanical resistance, sealing, and safety. A custom LTP plastic enclosure, designed for these demanding environments, is the ideal solution to meet these challenges. But how can sealing and durability be combined in tough conditions? The answer lies in LTP enclosure technology.

Technical challenges of demanding industrial environments

Industrial environments present numerous challenges for electronic equipment. These must be protected against external conditions such as humidity, high temperatures, shocks, and vibrations. One of the main challenges is sealing, which must prevent the ingress of water, dust, and other contaminants while maintaining optimal performance.

Additionally, thermal resistance is a key criterion. Equipment must withstand temperatures ranging from -20°C to +80°C without performance degradation. Under these conditions, the robustness of the enclosures becomes crucial, highlighting the importance of choosing an appropriate plastic material capable of resisting mechanical and thermal shocks.

LTP enclosure technology solutions: Custom plastic enclosures

The LTP enclosure technology enables the design of solutions tailored to these demanding environments, without requiring specific moulds.

Here are the main advantages of this process:

- No initial investment: With no need for specific moulds, you save on tooling costs and large-scale production expenses.

- Flexibility: You can modify and adjust your requirements at every stage of design and between production runs, ensuring optimal adaptation to your technical needs.

- Customisation: Each project benefits from a 100% tailored solution. The enclosure is designed to exact dimensions, technical constraints, and aesthetic requirements of the final product.

- Fast turnaround: Your prototypes or small series can be delivered within 2 to 6 weeks, allowing you to meet your project deadlines.

- Flame-retardant plastics: On request, you can opt for flame-rated plastic materials, essential for compliance with safety standards in sensitive environments.

- Eco-design: The possibility of choosing environmentally friendly solutions, contributing to a sustainable development approach.

- Aesthetic finishing: We offer aesthetic finishes such as painting or marking to enhance the integration of the enclosure into its final environment.

Case study: Protecting sensitive equipment

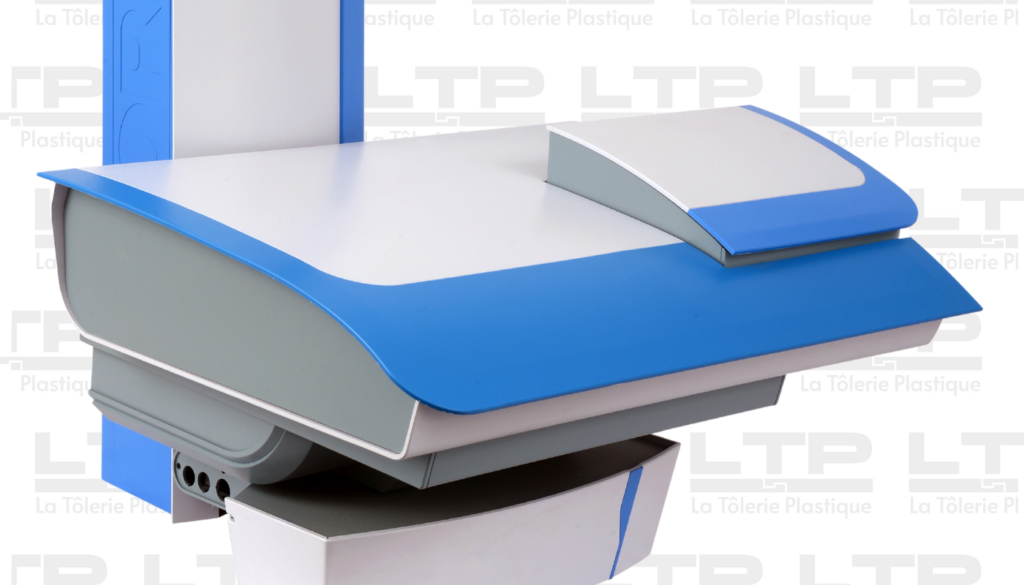

A concrete example of the efficiency of LTP enclosure technology is the design of custom enclosures for electronic devices used in spectrometry. These devices require protection against extreme conditions, including variable temperatures, strong vibrations, and high humidity. By using LTP enclosure technology solutions, the client was able to obtain perfectly adapted enclosures, ensuring not only optimal protection but also increased durability – all without the high costs of a specific mould.

Why choose LTP enclosure technology?

Choosing LTP means opting for a flexible, cost-effective, and custom solution that meets the strictest requirements of industrial environments. Our electronic enclosures offer superior protection while ensuring rapid and personalised production. You also benefit from the expertise of a company capable of designing products tailored to your specific needs while complying with safety and aesthetic standards.

📄 Contact us today to discuss your custom enclosure needs and discover our innovative solutions.

📞 Phone: 0033 (0)2 35 54 63 40 | 📧 Email: sales@ltp.fr