Since 1985, LTP has been manufacturing plastic enclosures using a unique and reliable technology developed by our founder: «Plastics Sheet Machining, Bending & Mounting Technology.» This mould-free process allows for the production of bespoke plastic housings in small and medium batches, tailored to meet our clients’ specific needs. Located in Octeville-sur-Mer, near Le Havre, our workshop ensures rapid production times.

Our fully customisable enclosures, covers, and parts cater to various industries, including industrial, beauty, and healthcare sectors. They are ideal for use in laboratories to house and protect medical equipment.

A Unique Process for Small and Medium Batches

Our Plastics Sheet Machining, Bending & Mounting Technology offers numerous advantages for manufacturers and clients alike:

These include:

- 100% Customisation: Products can be tailored to specific technical requirements and finishes without dimensional constraints.

- No Mould Investment: Ideal for small to medium quantities, avoiding the high costs of mould creation.

- Rapid Industrialisation: Quick turnaround from development and design to prototype and initial series.

- Design Flexibility: Easily accommodate design changes, dimensions, or customisations without additional costs.

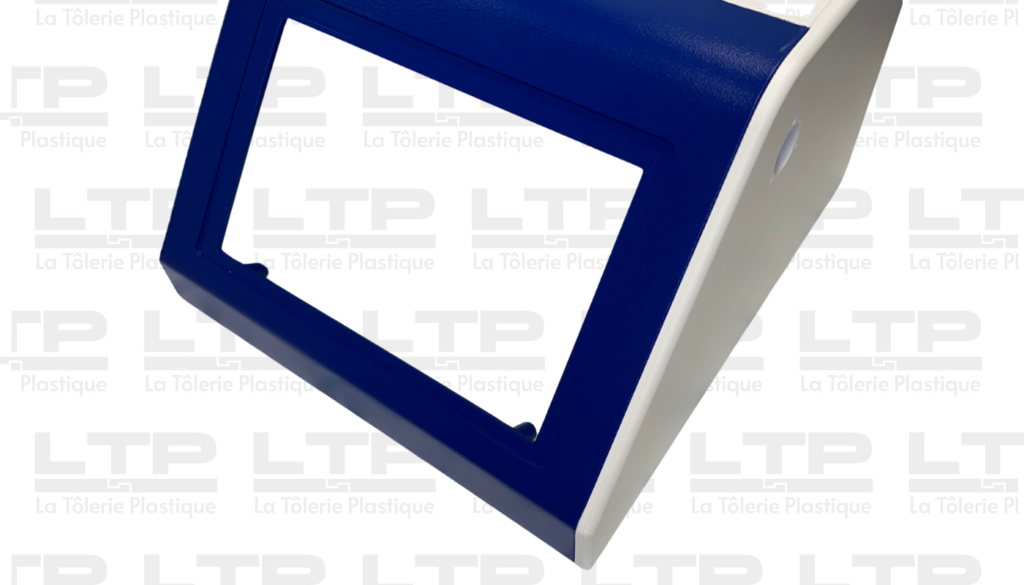

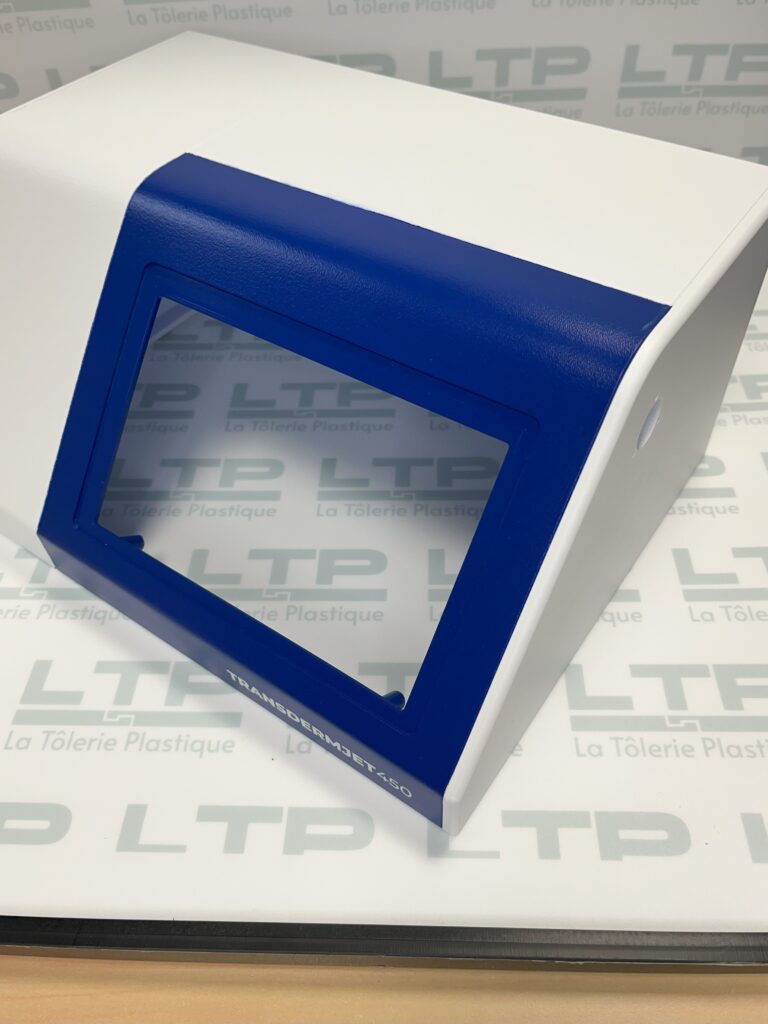

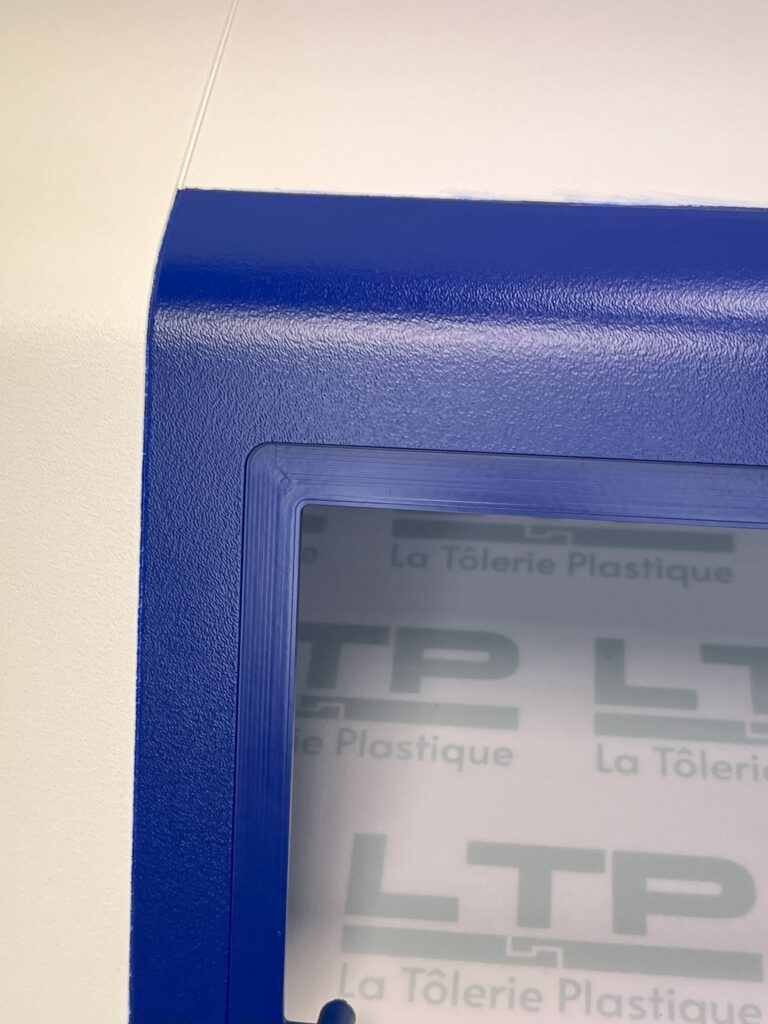

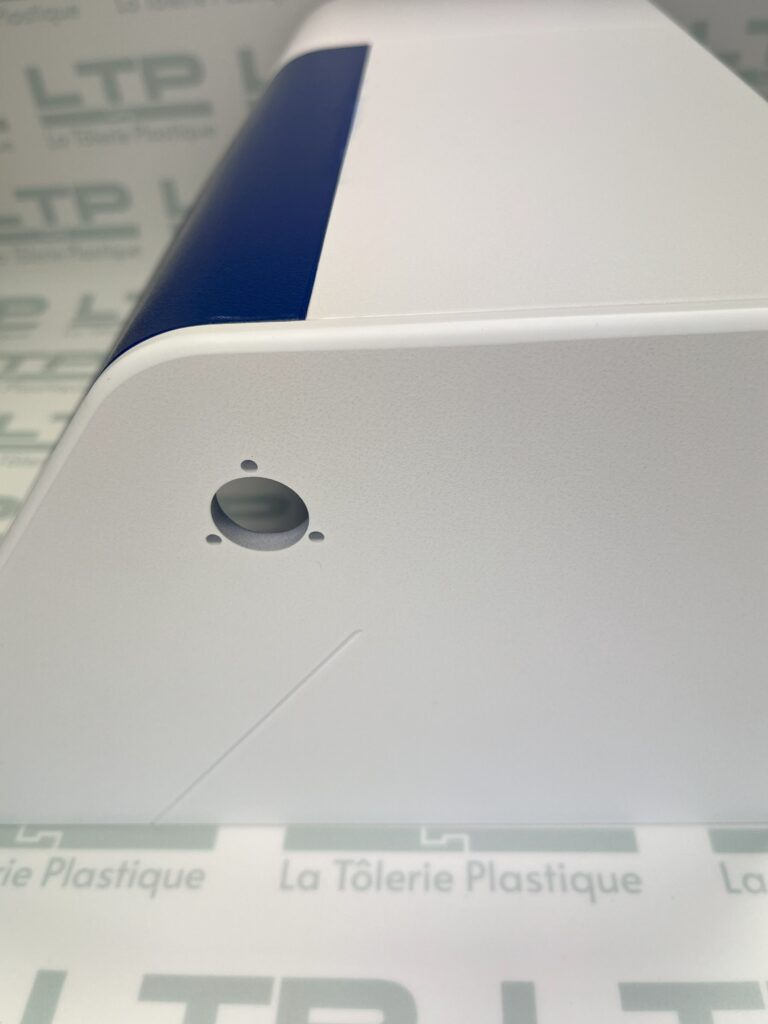

Medical Device Application Example

For nearly 40 years, LTP has been mastering this technique, producing approximately 200,000 housings and enclosures annually.

For instance, a laboratory required a bespoke hood-shaped housing, modifiable between series, producing around 20 units annually over several years. Our Plastics Sheet Machining, Bending & Mounting Technology process proved cost-effective compared to mould investment. We delivered a custom hood with copper shielding and a durable varnish finish, meeting the client’s specific laboratory requirements.

All production stages of a plastic electronic enclosure are handled by our team in our workshop, ensuring comprehensive support and control over production timelines and costs.

To learn more about our Plastics Sheet Machining, Bending & Mounting Technology process, we invite you to contact us. We are here to provide information and offer personalised quotes for your projects.

LTP: Your Partner for Custom Plastic Enclosures, Housings, and Parts with Precise and Durable Marking

For engineers and technicians aiming to transform their electronic devices into commercial successes, our Plastics Sheet Machining, Bending & Mounting Technology process offers the perfect balance between 3D printing and injection moulding. Our NO-MOULD plastic process combines the flexibility of 3D printing with the reliability of injection moulding.

As a designer and manufacturer, we offer you a :

- No special moulds required, adapted to your needs,

- Flexibility for all modifications, without constraints,

- No major initial investment required,

- 100% adapted to your target and application.

Start your project with LTP today: Request Your Quote

Visit us to explore our showroom and manufacturing process: Google Maps

What do you think of this information? Tell us what you think:

Want to learn more about our process? Schedule your Discovery Session on Teams exclusively for your team, live in 30 minutes!

Contact Us Now: For further information and to contact us, please visit our contact page.