The Importance of the Flexibility of a Pre-engineered and Customised LTP Enclosure with Mouldless Plastics Technology

Pre-engineered and customised with electromagnetic and wave transmission protection

The combination of electromagnetic protection and wave transmission is essential for many modern applications. For example, the selective application of copper paint to pre-designed plastic enclosures can help mitigate electromagnetic interference while maintaining effective connectivity. This is particularly important in areas such as IoT, where connected devices need to work in harmony without disturbing the electromagnetic environment.

Pre-designed and made-to-measure to optimise space and meet maintenance constraints

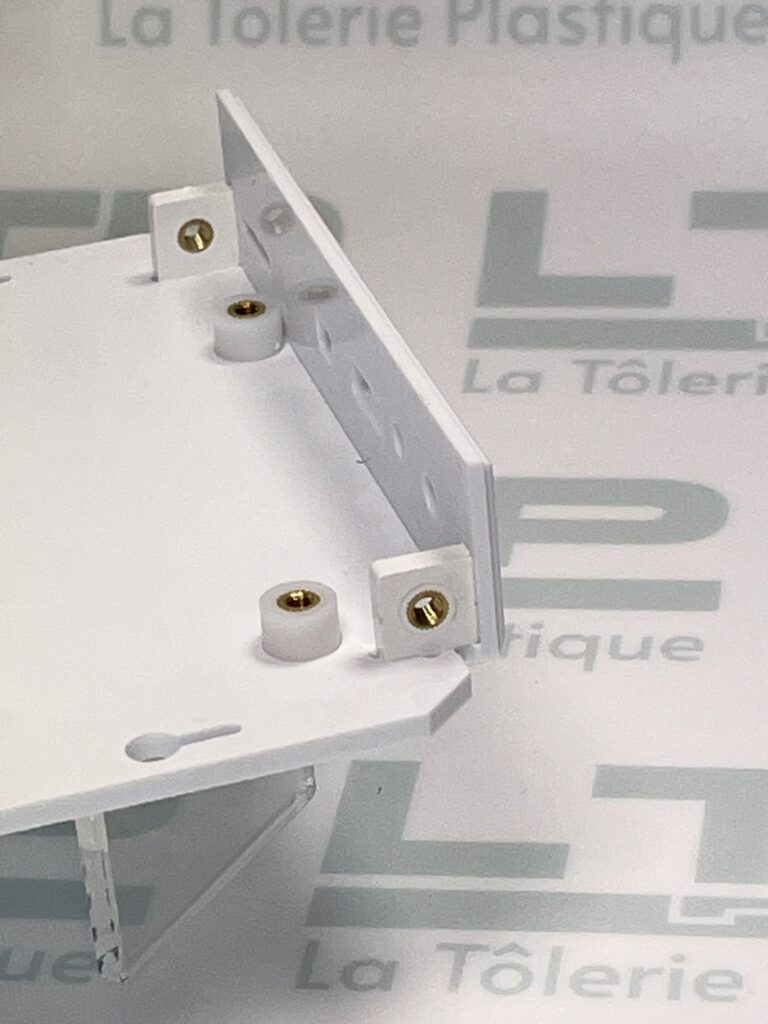

Another key aspect of enclosure design is optimising the space required for electronic equipment. Designers need to ensure that each component is positioned to maximise efficiency while respecting physical constraints. For example, access to the battery tray and the integration of suitable locking systems are crucial for equipment maintenance. These considerations ensure that the equipment remains operational and easy to maintain throughout its lifecycle.

Example of a project: Customised enclosure for a detection system

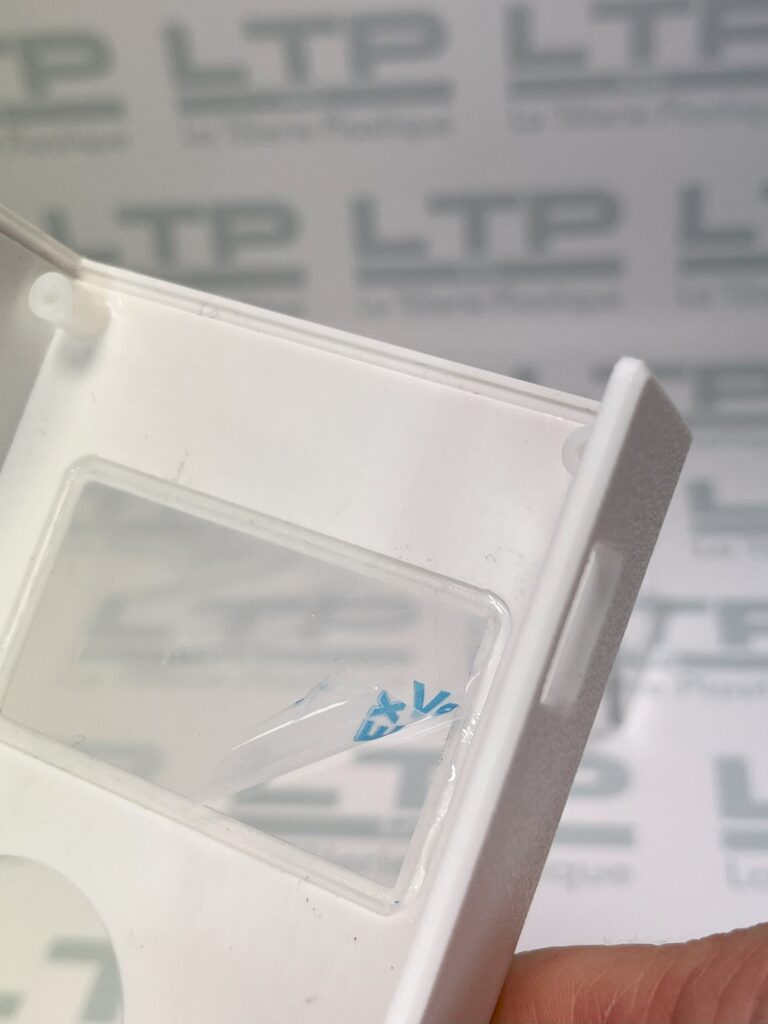

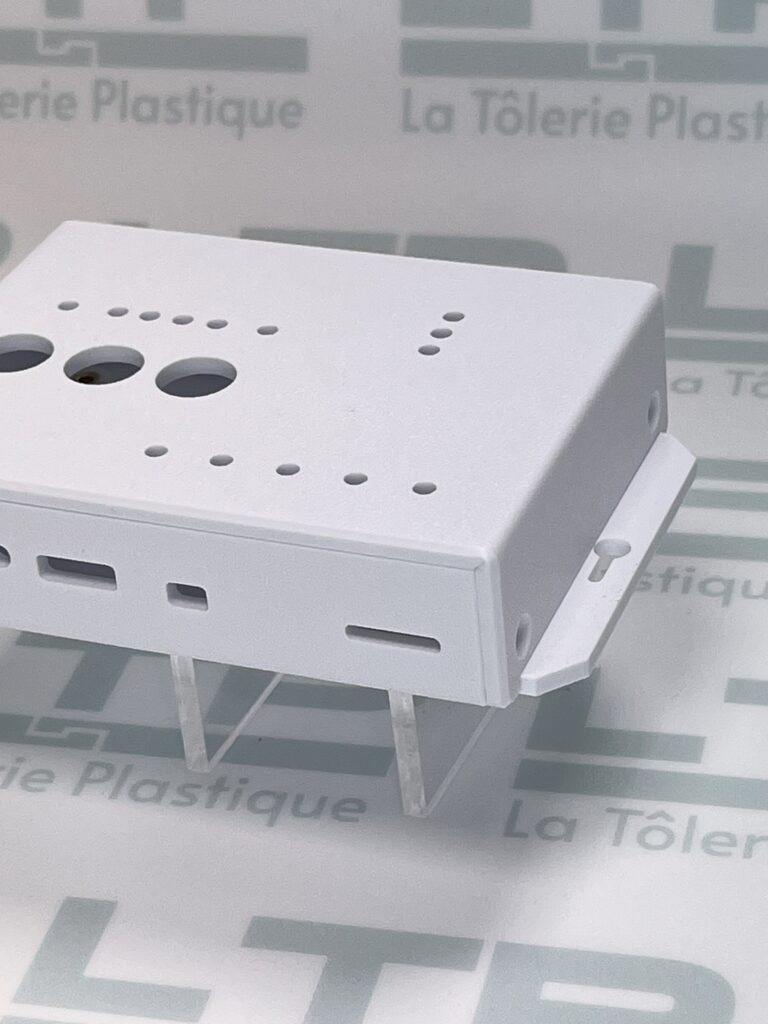

Let’s take the example of a project carried out for a customer in the security sector. The objective was to design a pre-designed plastic enclosure that could accommodate advanced detection technology while providing electromagnetic protection. Using a customised approach, our team integrated a membrane keyboard and touch screen, while optimising space for connectivity such as HDMI and USB ports.

The production stage included specific tolerance points, ensuring that each enclosure met strict quality standards. This process provided the flexibility to meet the customer’s needs, even during the product development phases.

Conclusion

Pre-designed plastic cases from the ElectroniCase by LTP custom range are an ideal solution for companies wanting to innovate while maintaining flexibility in their electronic projects. By taking into account the requirements of protection, space optimisation and maintenance, LTP is positioned as a reliable partner for the development of your products.

Contact LTP for Your Design and Manufacturing Needs

To find out how our pre-engineered plastic enclosure solutions can meet your specific needs, please contact us. Our team of experts is ready to support you at every stage of your project. Together, we can turn your ideas into reality! Visit our website for more information and to discuss your projects with us.

As a designer and manufacturer, we offer you a :

- No special moulds required, adapted to your needs,

- Flexibility for all modifications, without constraints,

- No major initial investment required,

- 100% adapted to your target and application.

Start your project with LTP today: Request a quotation now !

Come and see us to discover our showroom and our production facilities: Google Maps

What do you think about this information ? Tell us your opinion: Google Business

Would you like to find out more about this process? : Schedule your exclusive Teams Discovery Session for your teams; live in 30mins! j.bertin@ltp.fr

Contact us today: Form and contact details for our company

+33 2 35 54 63 40

Email : sales@ltp.fr